Before reading this, you need to view the YouTube video “SHOP TIPS #177 Making Larger Dials for the Logan Lathe part 1 tubalcain” which can be found at: https://www.youtube.com/watch?v=Y0TwJQ-0FBw&list=UUKLIIdKEpjAnn8E76KP7sQg View SHOP TIPS #178 to 180 as well and then the following will make more sense. These are part of a wonderful series of shop videos by a machinist called Tubalcain or Mr. Pete that have taught me a great deal about metalworking.

I needed to make a couple of shafts with shallow splines to assemble to a pair of U-joints and a steering wheel that I plan to use for a vehicle I am building. As an amateur machinist, I was at a loss as to how to make the shafts to exactly match the 29 splines in the U joints and the 34 splines in the wheel. Then I saw Mr. Pete’s outstanding video series on making larger dials for the Logan lathe. As soon as I saw it, I knew I had the answer.  Rather than trying to find two saw blades with the correct number of teeth, I decided to make a plate with two rows of holes, 34 holes on a 5.5 inch circle and 29 holes on a 4.75 inch circle. Then with a fixed pin to drop into the holes, I could index my lathe around and use a tool mounted sidewise in the regular tool holder to cut in the splines just like Mr. Pete did to cut in his dial markings.

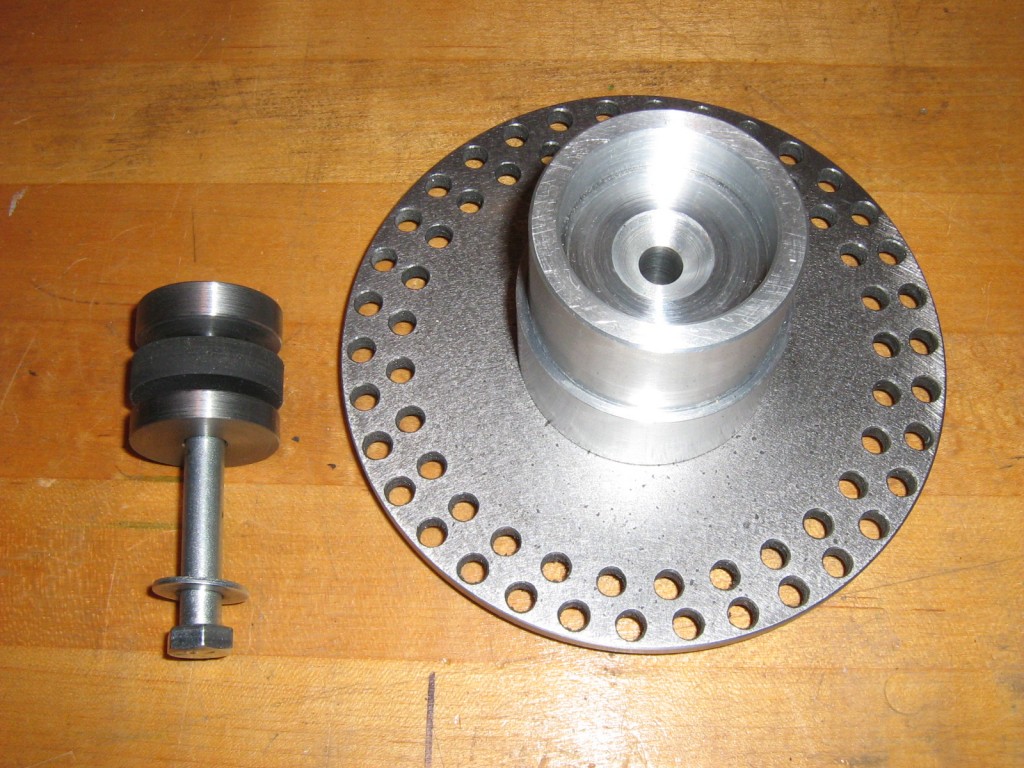

Rather than trying to find two saw blades with the correct number of teeth, I decided to make a plate with two rows of holes, 34 holes on a 5.5 inch circle and 29 holes on a 4.75 inch circle. Then with a fixed pin to drop into the holes, I could index my lathe around and use a tool mounted sidewise in the regular tool holder to cut in the splines just like Mr. Pete did to cut in his dial markings.

I used the technique that Mr. Pete showed in “Machine Shop Tips #153 Bolt Circles DRO Method” and that Tom Lipton used in his “Autometric Jig Bore Resurrection” series <https://www.youtube.com/user/oxtoolco> to make the bolt circles using my Bridgeport mill and DRO.

I didn’t want to use Mr. Pete’s method to attach the plate to the lathe because I wanted the shaft that I was cutting the splines on to be able to pass partway through the spindle. The mounting method that I hit on was to machine an aluminum rod to bolt onto the plate on one end and to bore the other end for a slip fit with the outside of the lathe  spindle. Two steel disks were machined to fit into the inside of the spindle and sandwiched between them is a disc of rubber. When the assembly is slipped onto the end of the spindle and the bolt is tightened, the rubber expands to hold the plate firmly in place. This method allows the plate to be mounted without removing any of the guards from the lathe.

spindle. Two steel disks were machined to fit into the inside of the spindle and sandwiched between them is a disc of rubber. When the assembly is slipped onto the end of the spindle and the bolt is tightened, the rubber expands to hold the plate firmly in place. This method allows the plate to be mounted without removing any of the guards from the lathe.

Here’s the splines being cut and the final result. A nice fit in the U-joint.